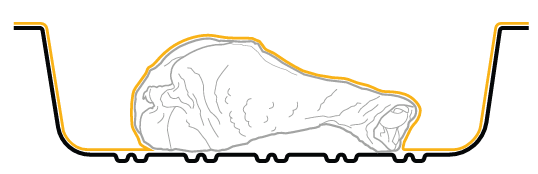

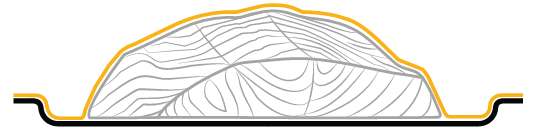

Skin film

Skin film differs from traditional lidding films by wrapping itself perfectly around the product under vacuum conditions to show it off with a 3D effect on trays or skin boards. This film provides a tight seal around the product, minimizing air contact for extended shelf life. Skin film works well for perishable foods like meat, cheese, and seafood. Our skin film is glossy, high-quality, and transparent.

With horizontal form-fill-and-seal (HFFS) automation and tray sealing capabilities, you can seal your food products in high volumes in a shorter amount of time. And don’t worry about punctures; this durable film is resistant to pokes and sharp edges.

Skin film differs from traditional lidding films by wrapping itself perfectly around the product under vacuum conditions to show it off with a 3D effect on trays or skin boards. This film provides a tight seal around the product, minimizing air contact for extended shelf life. Skin film works well for those quick-to-expire foods like meat, cheese, and seafood. Our skin film is glossy, high-quality, and transparent.

With horizontal form-fill-and-seal (HFFS) automation and tray sealing capabilities, you can seal your food products quickly and more efficiently. Produce high volumes in a shorter amount of time. And don’t worry about punctures, this durable film is resistant to pokes and sharp edges.

Skin Film

Features

Forms tightly around the product

Exceptional durability & puncture resistance

High barrier properties

Ultra clear film for product demonstration

SKIN FILM

Applications

Vacuum skin packaging (VSP)

Vacuum skin pack (VSP)

Pro-skin packaging

Pro-skin packaging

Other

Films

Have a project in mind?

Our packaging experts are happy to help. We can provide free consultations and pricing for tailored, high-quality solutions.